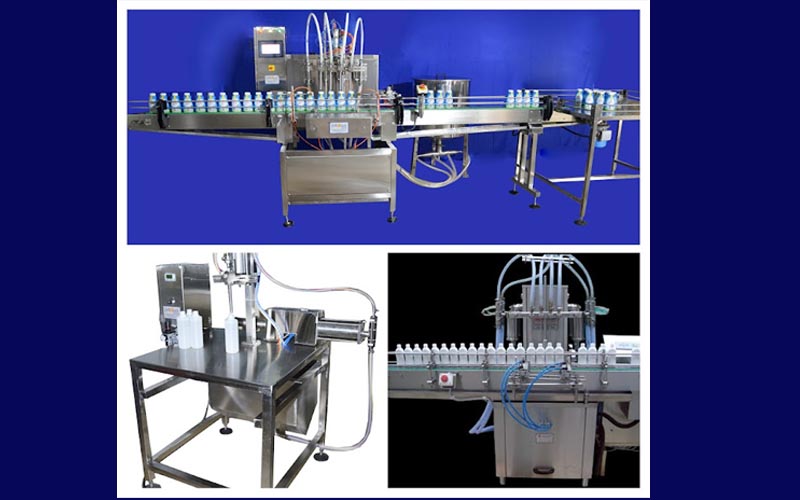

Liquid Filling Machines

Discover precision and efficiency with our cutting-edge Liquid Filling Machines, crafted to elevate your packaging experience. At Stillpack Solutions, we take pride in offering state-of-the-art filling solutions designed for a diverse range of liquid products.

Key Features:

1. Versatility in Filling

Our liquid filling machines are ideal for packing various liquid products, from medicines and pesticides to chemicals to Paints and oils. The versatility of our machines makes them suitable for a wide array of applications

2.Easy Operation and Energy Efficiency

Experience seamless operations with our user-friendly machines that are not only easy to operate but also energy-efficient. We prioritize efficiency to ensure optimal performance in your production processes

3.PLC Controlled Systems

4.Benefit from advanced control systems with our liquid filling machines. The PLC-controlled systems guarantee precision, accuracy, and seamless integration into your production line.

4.Adaptable for Various Liquids

5.Whether it's free-flowing liquids or those with specific properties, our machines accommodate all types of liquid products without the need for change parts

5.Servo and Volumetric Pneumatic Filling Technology

Our machines employ cutting-edge New Generation Servo and volumetric-piston filling technology, ensuring accurate and consistent filling for various liquid viscosities. suited for pharmaceutical, chemical, paint, Adhesives, oil and other special applications

6.Capacity Range:

Choose from different models to meet your specific capacity requirements. Our machines can fill liquid volumes ranging from 10 ml to 50 ml, 50 ml to 300 ml, and 100 ml to 1 liter and above.

7.Adaptable for Various Liquids:

Whether it's free-flowing liquids or those with specific properties, our machines accommodate all types of liquid products without the need for change parts.

8.Heat and Chemical Resistant::

Our liquid filling machines are equipped with heat-resistant cylinders and chemical-resistant jacketed hoppers, making them suitable for hot filling processes.

9.Foaming and Spillage Control:

Experience precision in every fill with our diving nozzle system that effectively controls foaming and spillage, ensuring a clean and efficient packaging process.

10.Scalable Configuration:

Choose from standalone machines with 1 to 4 filling nozzles and Automatic machines from 2 to 10 filling nozzles, providing flexibility and scalability to match your production needs.